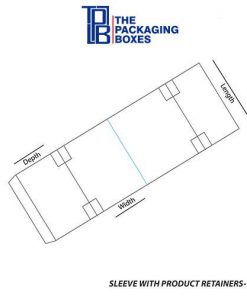

Bowl Sleeve

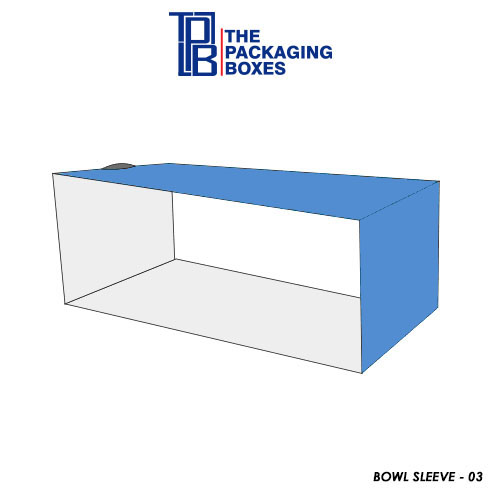

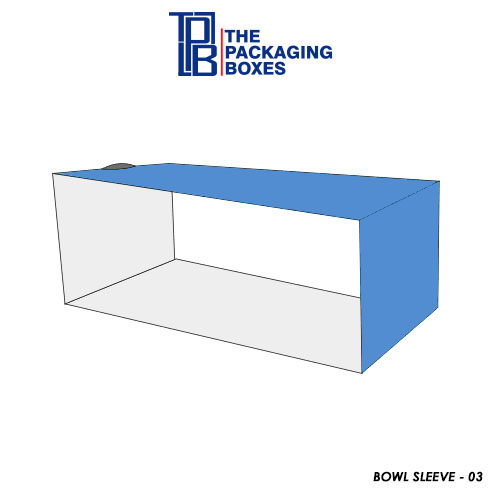

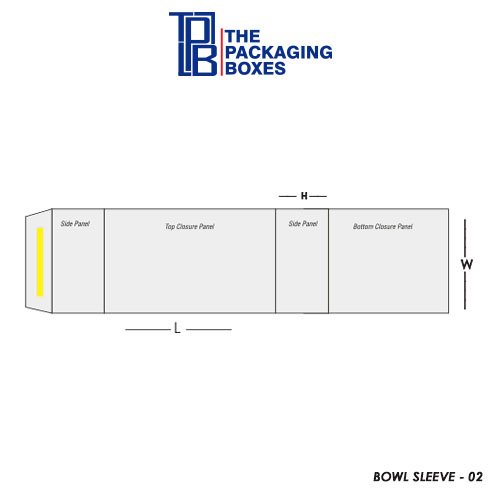

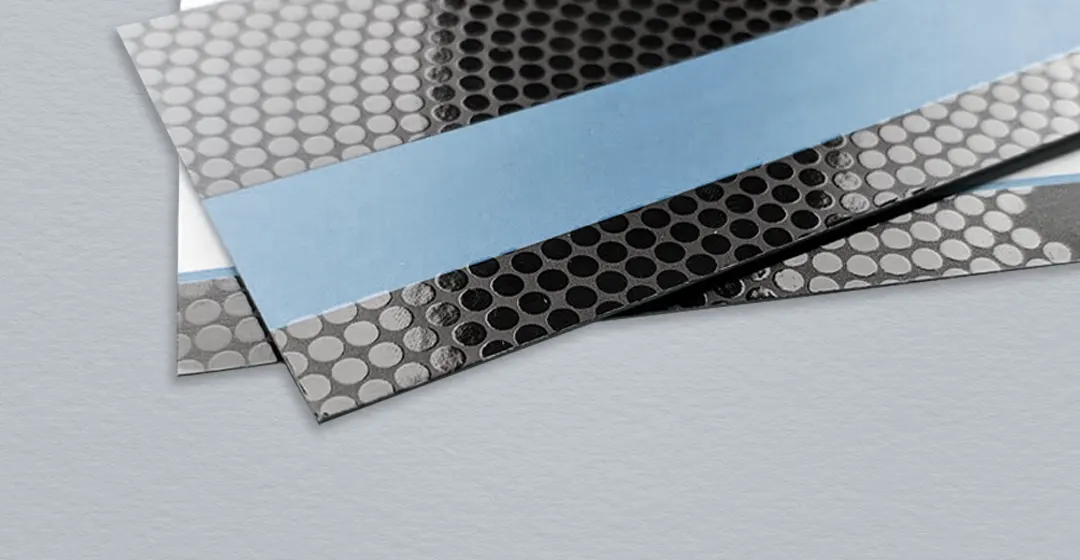

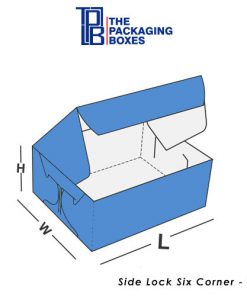

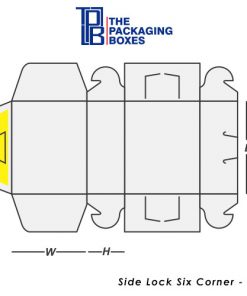

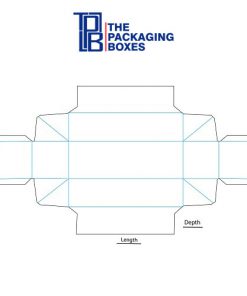

Bowl sleeve boxes are one of the best options in the market to provide additional security to products that are breakable, for example, glass, ceramics, and such. These packaging boxes surround the box which contains the product in a strong grip hold like a sleeve.

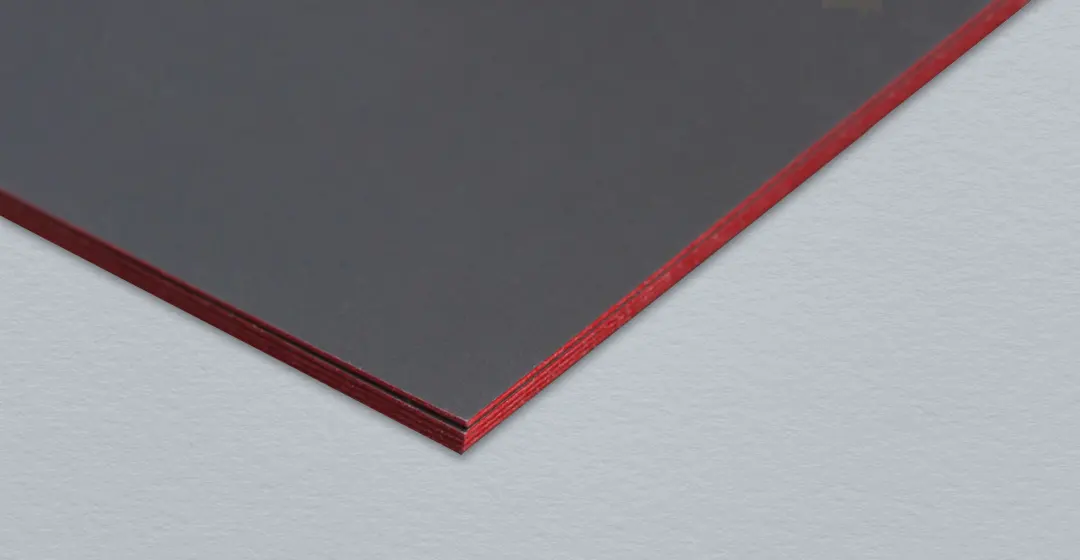

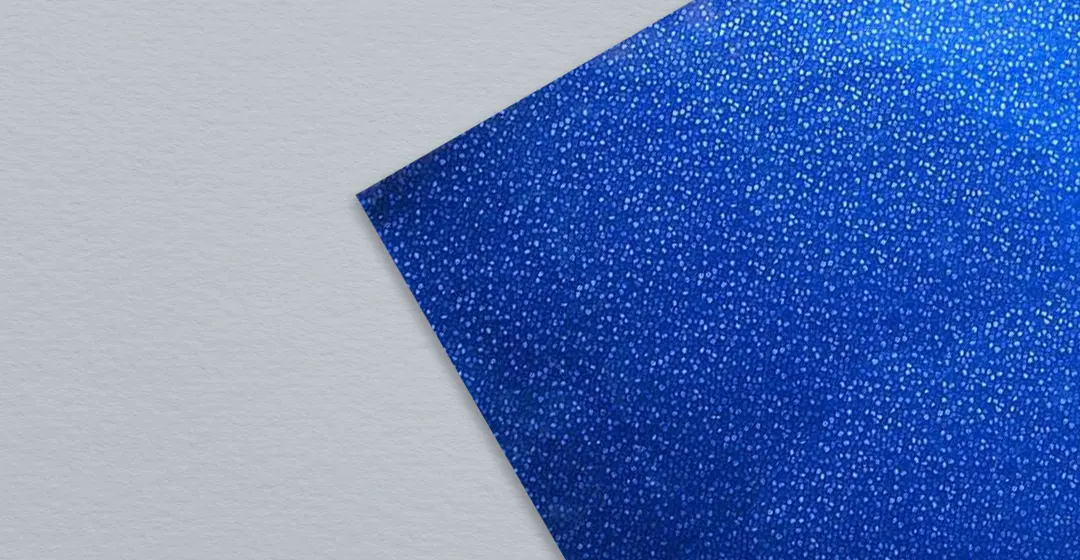

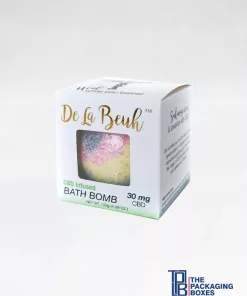

For wholesale custom printed bowl sleeve boxes, look no further than The Packaging Boxes. TPB takes care of every aspect of manufacturing the perfect bowl sleeve boxes for you. The Packaging Boxes offers one-of-a-kind bowl sleeve boxes that can be personalized in any way i.e. size-wise, appearance-wise, and material-wise, to suit your preferences and needs. TPB offers economical printing and packaging, as we do not charge anything for quotes, design support, digital mockups, add-ons to add to the aesthetics of your boxes and delivery. The Packaging Boxes is one of the most economical providers for custom bowl sleeve boxes.

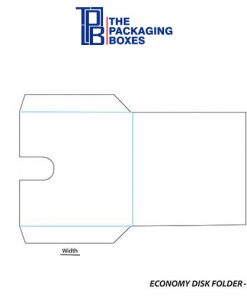

However, If this is not what you were looking for, you can always choose your style of Custom Figure And Pattern Boxes. Meanwhile, if it is what you looking for then just get in touch with The Packaging Boxes’ customer care for a free quote for a premium Custom Printed Bowl Sleeve Boxes.