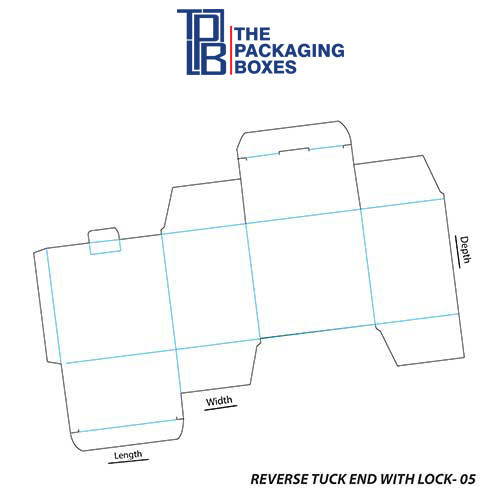

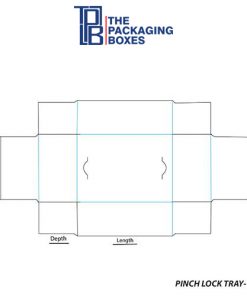

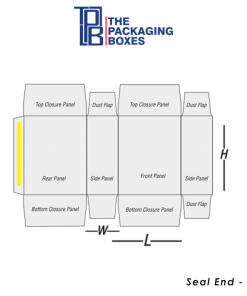

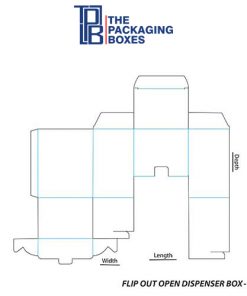

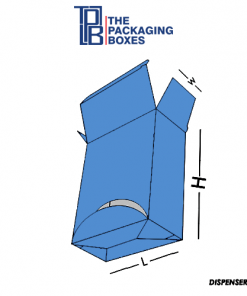

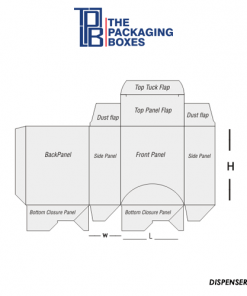

| Default process | Die cutting, gluing, scoring, perforation |

|---|---|

| Min.quantity | 50 |

| Options | Custom Window Cut Out, Multi Colour Foiling, Embossing, Raised Ink, PVC Sheet. |

| Paper stock | 280 GSM to 700 GSM (60lb to 400lb) Cardstock, Eco-friendly Kraft, E-Flute Corrugated, Bux-Board. |

| Printing | Cmyk, pms, no printing |

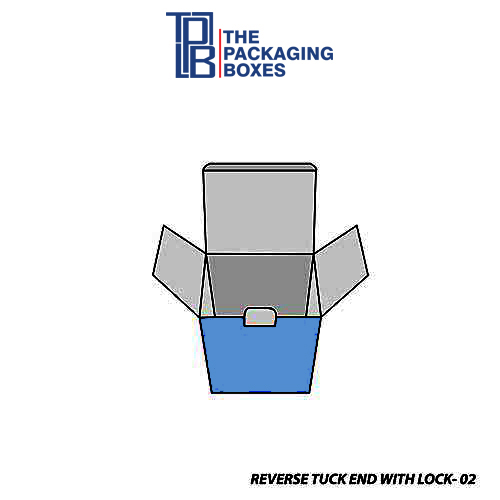

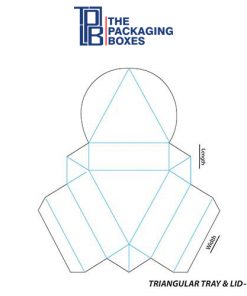

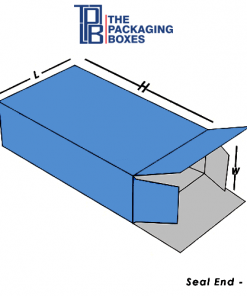

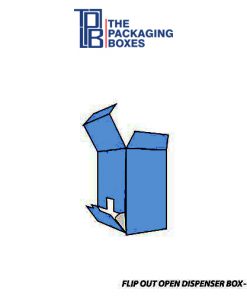

| Proof | Flat view, 3d mock-up, physical sampling (on Request) |

| Turn around time | 12-14 business days , rush |

Custom Structure

Fully customized rigid structures tailored to your specifications.

Leather Wooden

Meticulously crafted premium custom leather and wooden rigid boxes.

Custom Inserts

Fully customized rigid structures tailored to your specifications.

Custom Ribbons

Our Packaging Boxes Holds a Wide selection of custom luxurious ribbons for you to choose from.

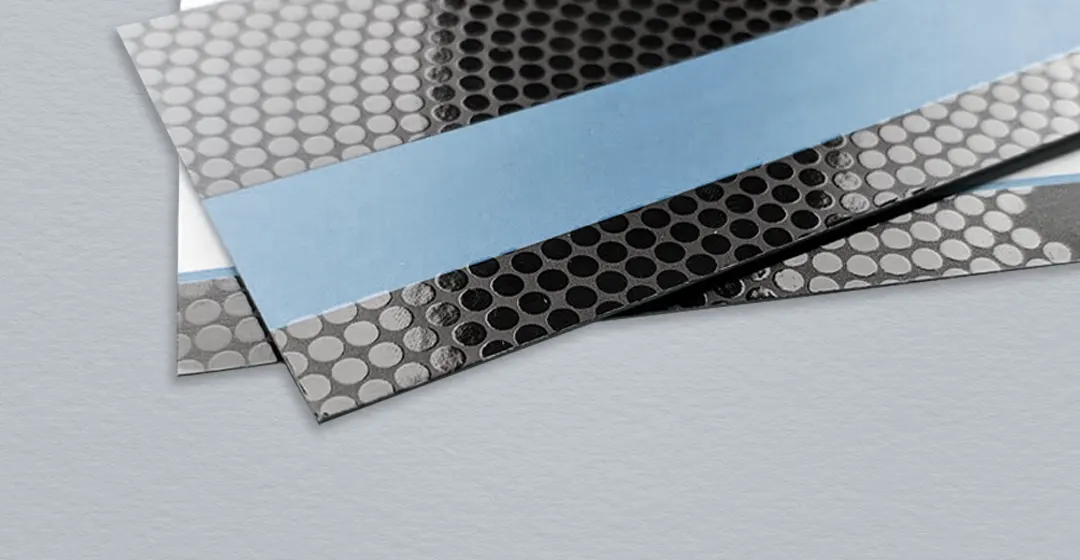

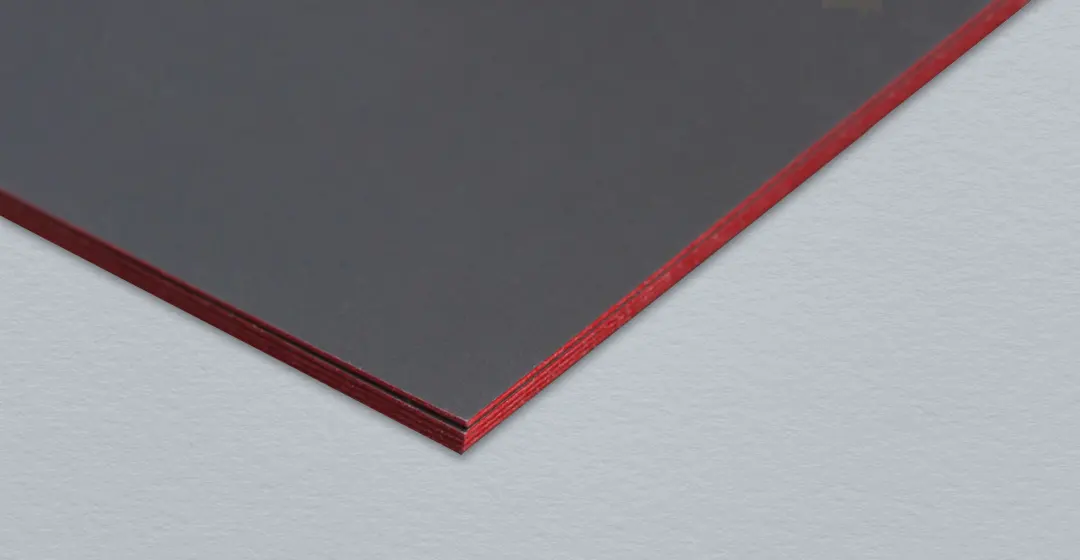

Unlimited Paper

Unlimited selection of textured and coloured paper for you to choose from.