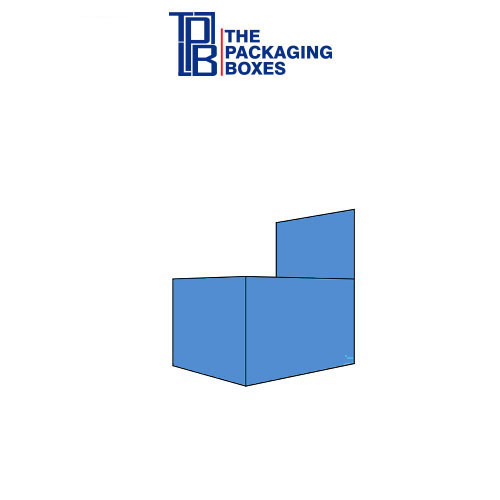

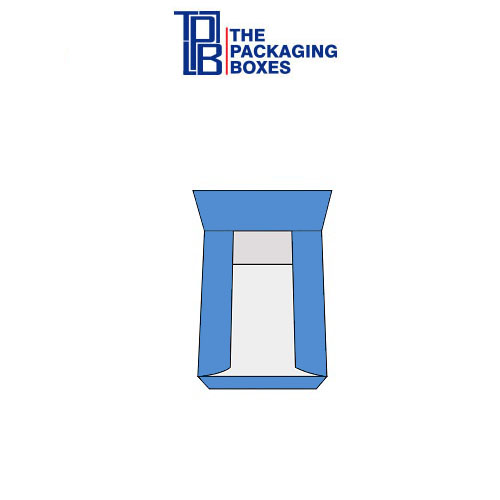

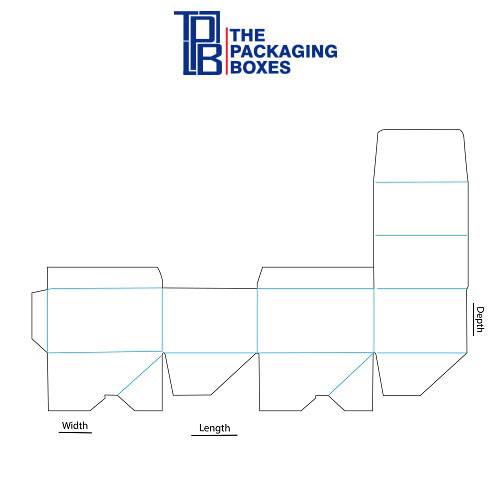

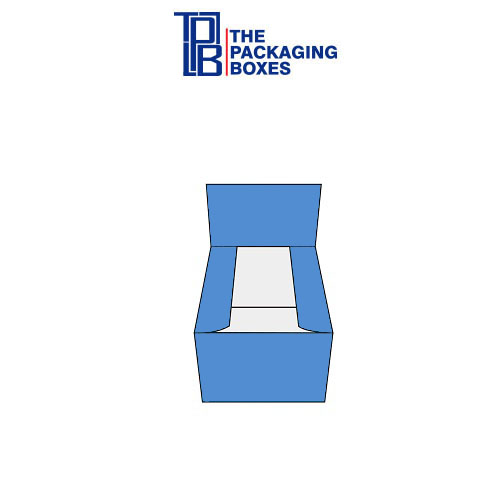

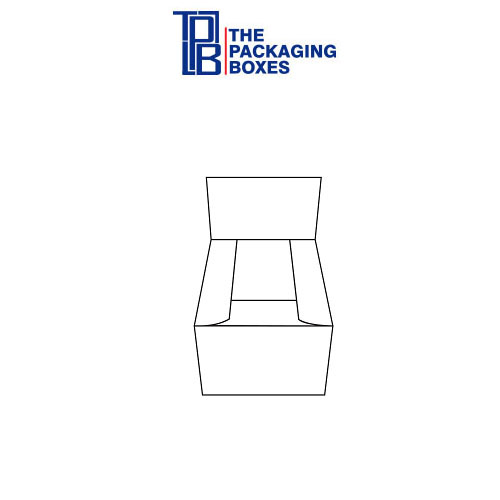

Display Box Auto Bottom

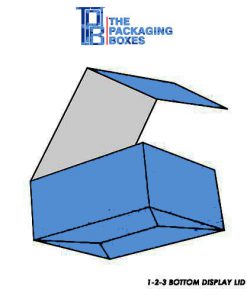

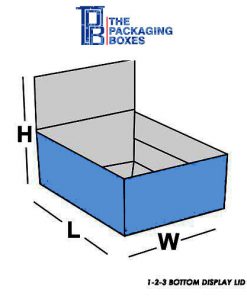

To keep the encased products safe the base of packaging boxes must be sturdy and reliable. Auto-bottom base is one of the most reliable locking systems when it comes to bespoke packaging. Where the flaps at the bottom interlock with each other easily and in an effective manner, the base of the box is successfully secured. If you are a retailer or a shopkeeper and are looking for box options to display your products, then might we suggest custom auto bottom display boxes?

The Packaging Boxes offers high-quality display boxes with an auto bottom locking system that can successfully display and contain products. Whether they are lightweight products like snacks or even medium-weight products like makeup foundations, these boxes can get the job done. Wholesale display boxes with auto bottom locking system by The Packaging Boxes are not only premium in quality but functional and affordable as well.

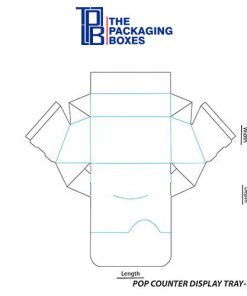

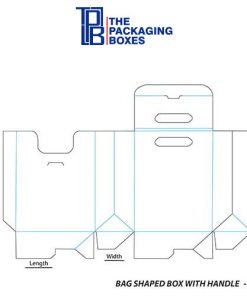

However, If this is not what you were looking for, you can always choose your style of custom showcase exhibit boxes. Meanwhile, get in touch with The Packaging Boxes’ customer care for a free quote for premium custom Display Box Auto Bottom Boxes.