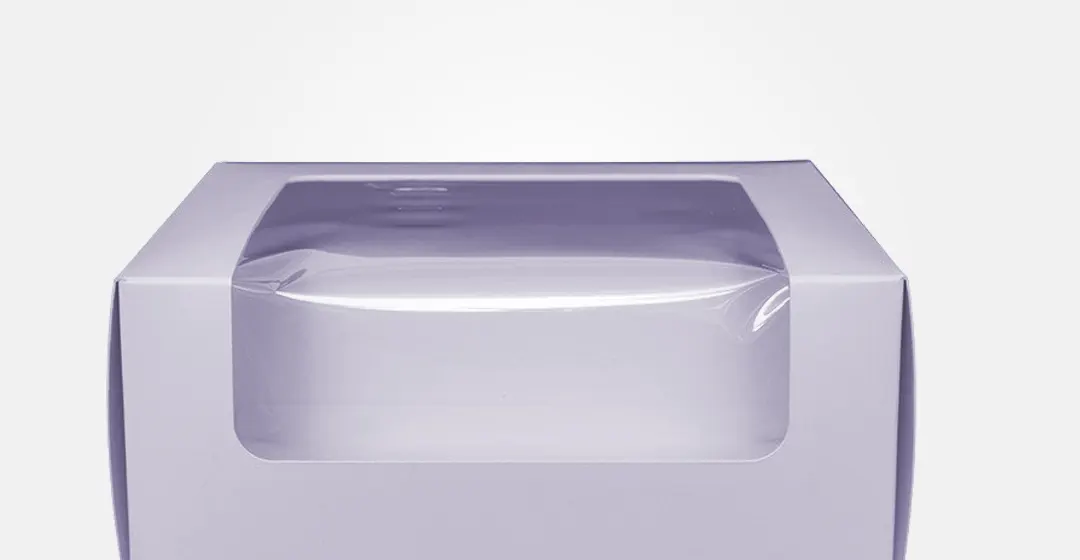

Shoulder Boxes

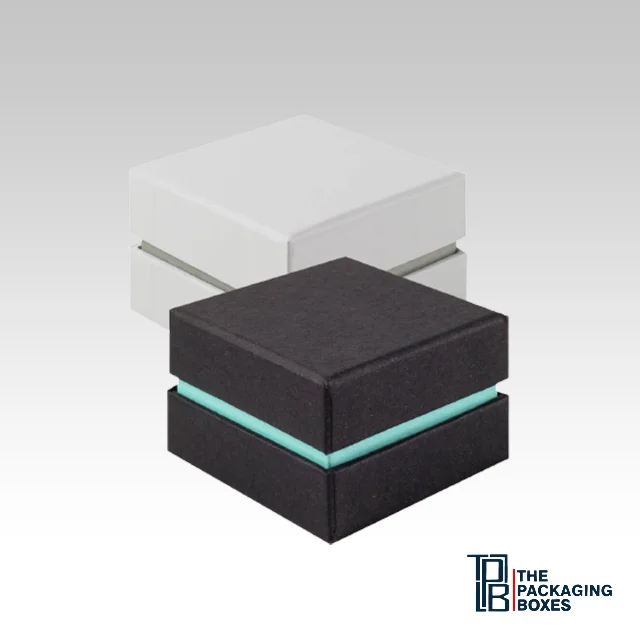

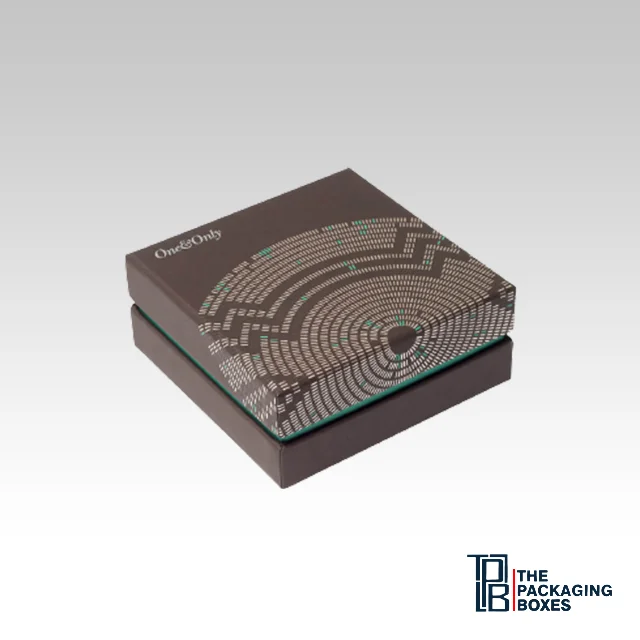

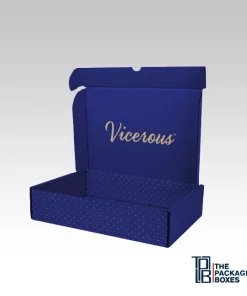

Are you wondering what Custom Shoulder Boxes are used for? Anything and everything. Their innovative yet elegant design makes them relevant for a variety of uses. Perfect for fragile and delicate gift items like jewellery, watches, perfumes, and tech accessories. Contrasting colour schemes and tight grip make them a popular choice in the luxury packaging market.

Depending on which product they carry, they can be produced in all shapes and sizes. We can add different styles and materials of inserts to provide superior protection to its contents. Discover your brand aesthetic and be mindful that your luxury boxes go hand in hand. Let’s make that first impression count!

TPB-UK has a team of design experts who have appropriate industry experience and knowledge to execute your ideas to excite potential customers at first sight. Our high-resolution printing technologies are best for catchy graphics, and a luxe finishing coat, whether matte or glossy, enhances them. We recommend highlighting your brand name or logo using gold or silver foiling or embossing/debossing techniques. We offer a quick turnover time of 6-9 business days and free of cost shipping all over the UK.

Contact us today and get started straight away!